How Vinyl Figures Are Made

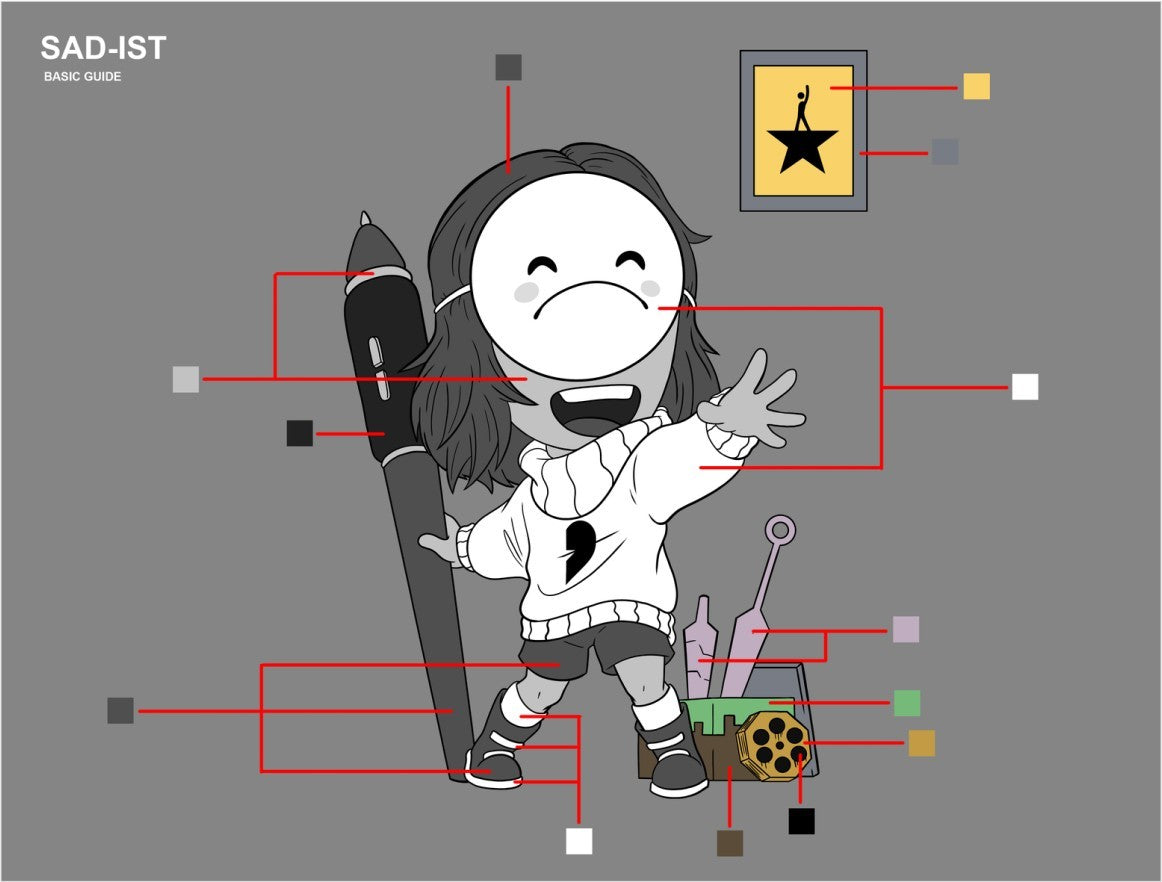

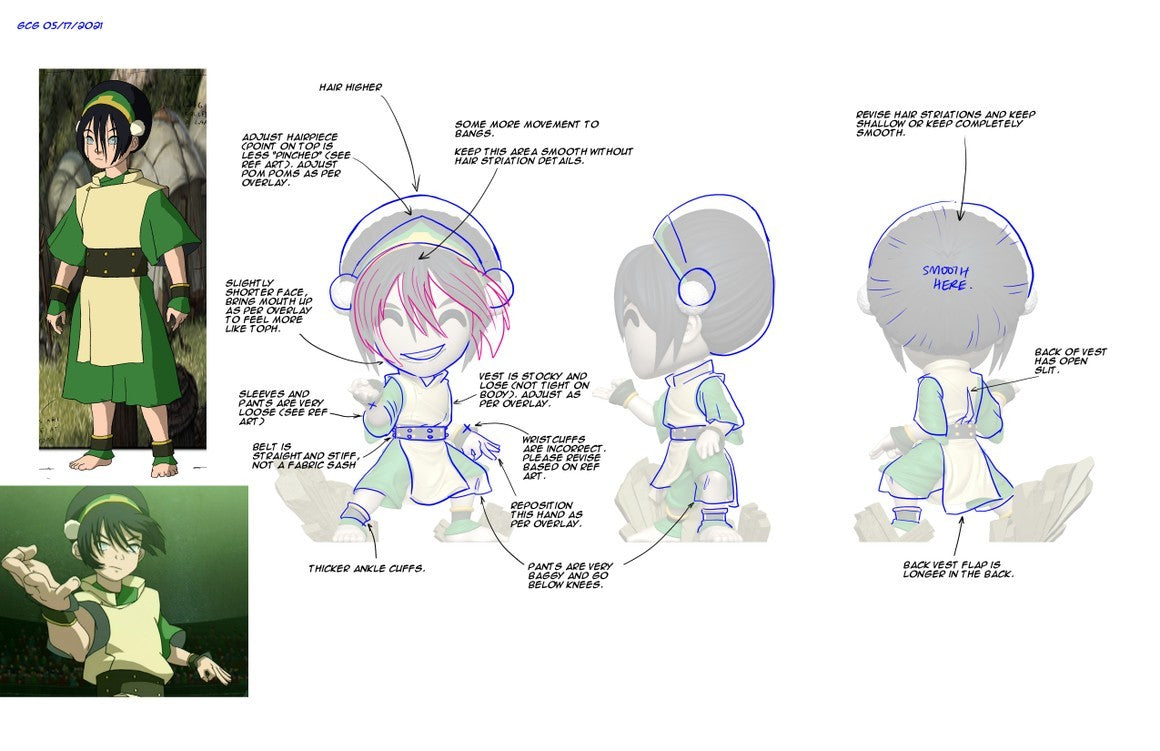

Concept

OPJOYS in-house artists sketch poses and moments to capture a character in collaboration with the person or team the OPJOYS is based on. For many designs we do live sketching sessions with screen-share, review mood-boards, or capture ideas through a form which covers everything head to toe for the OPJOYS. The polished concept is then shared with the creator, IP holder, or owner of the character for approval. Usually a few rounds of revisions are made to the concept based on feedback or areas of improvement.

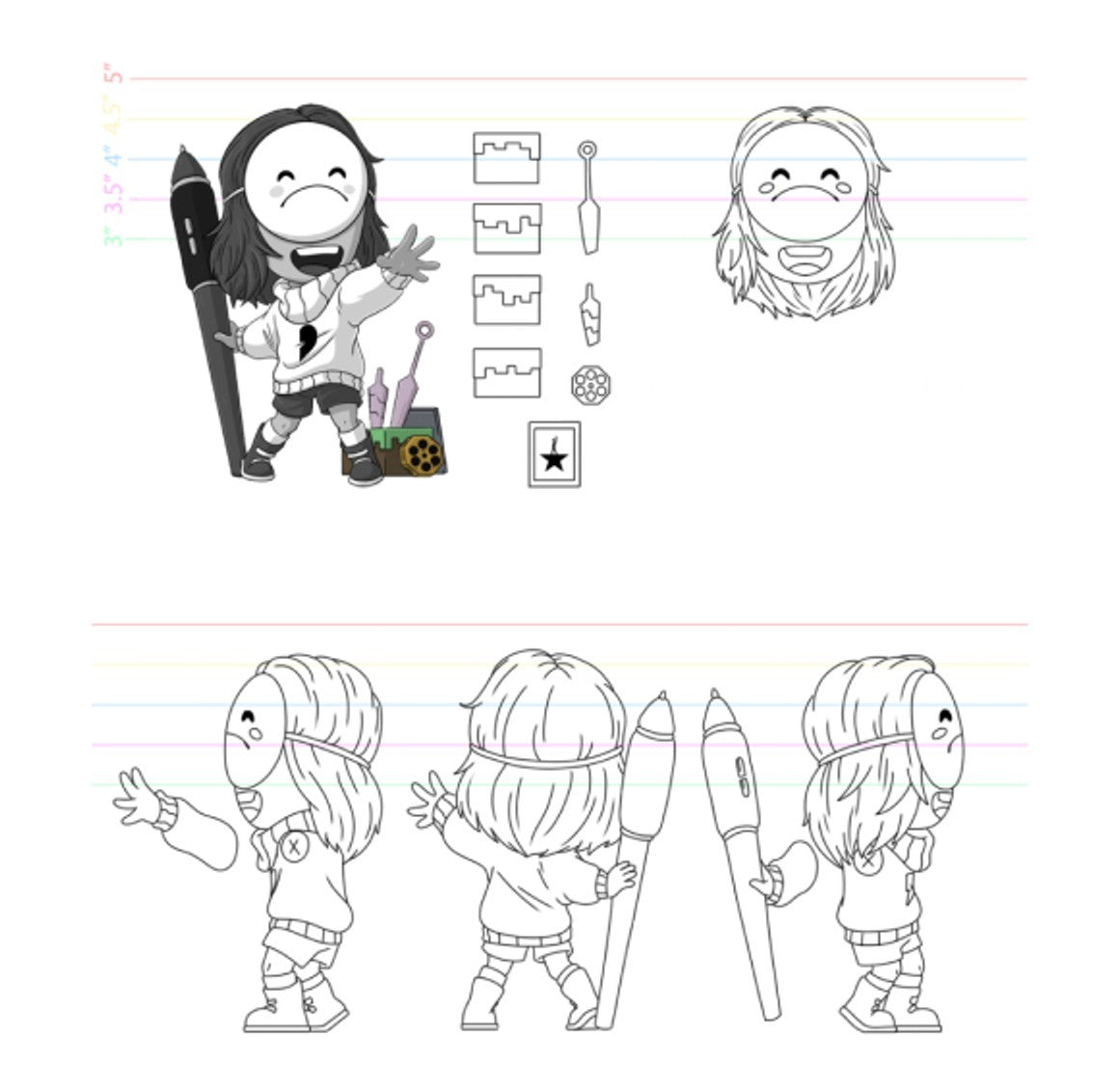

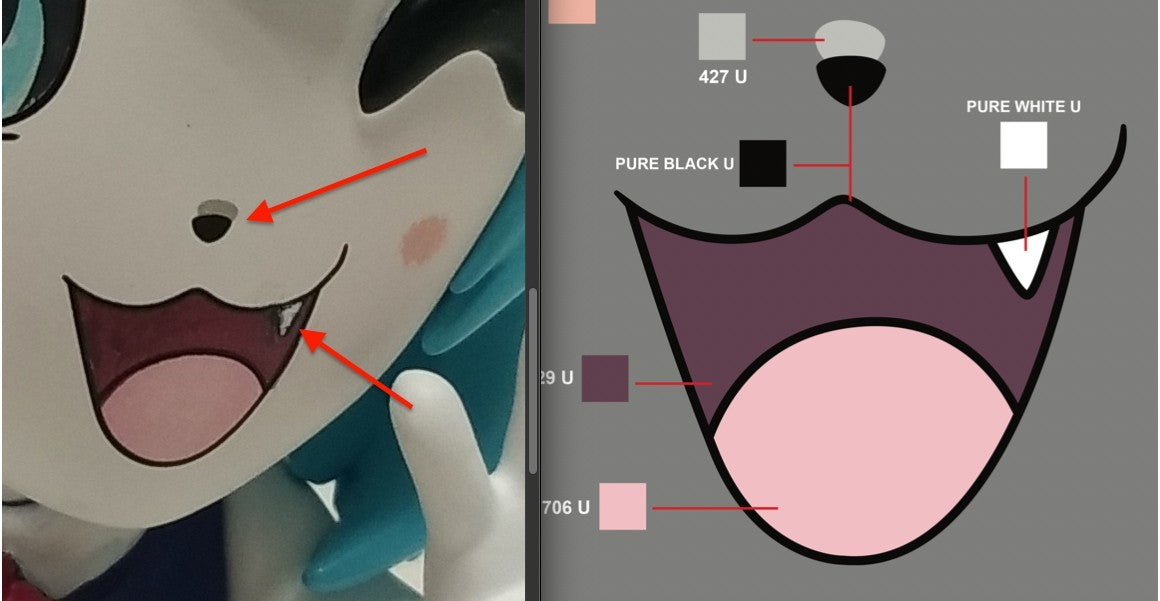

Turn-around and color guide

The OPJOYS concept artist creates a 4-point turn around of the concept to see how it will look in 3D and decides on the pantone colors that will be painted on the model. Over 3,000 pantone colors exist in varying shades and styles making the selection process very important to capturing the character in physical painted form.

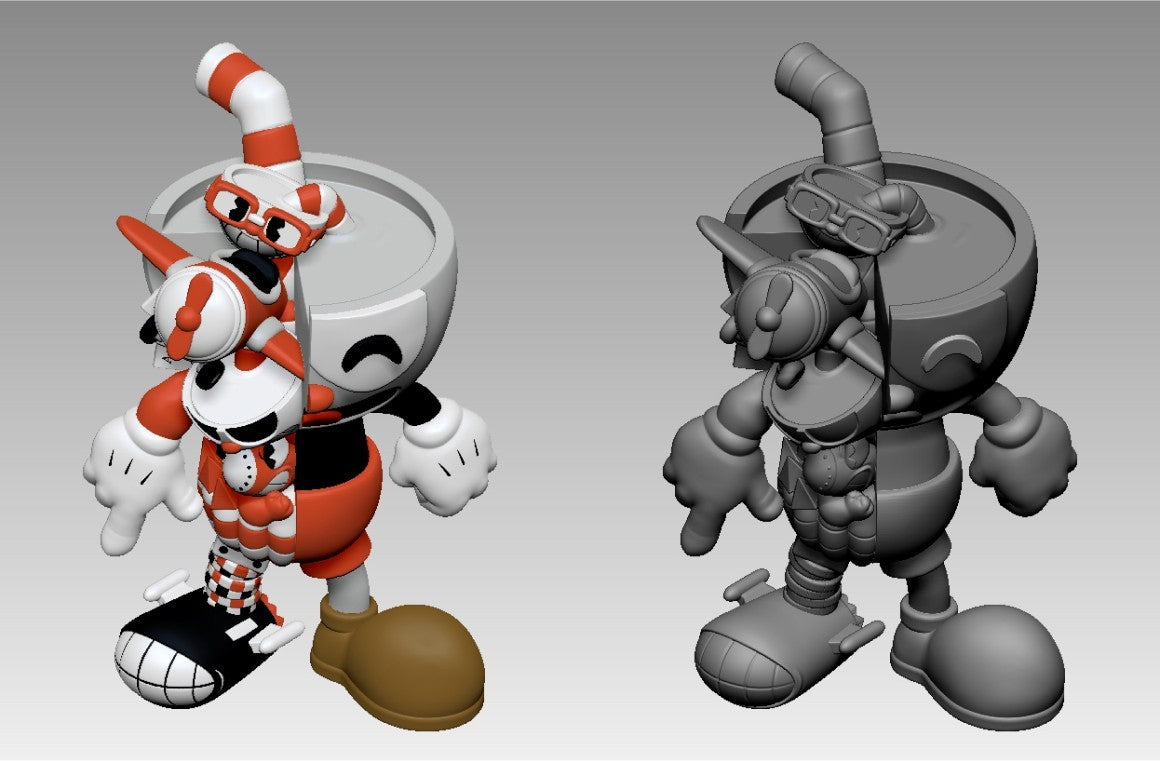

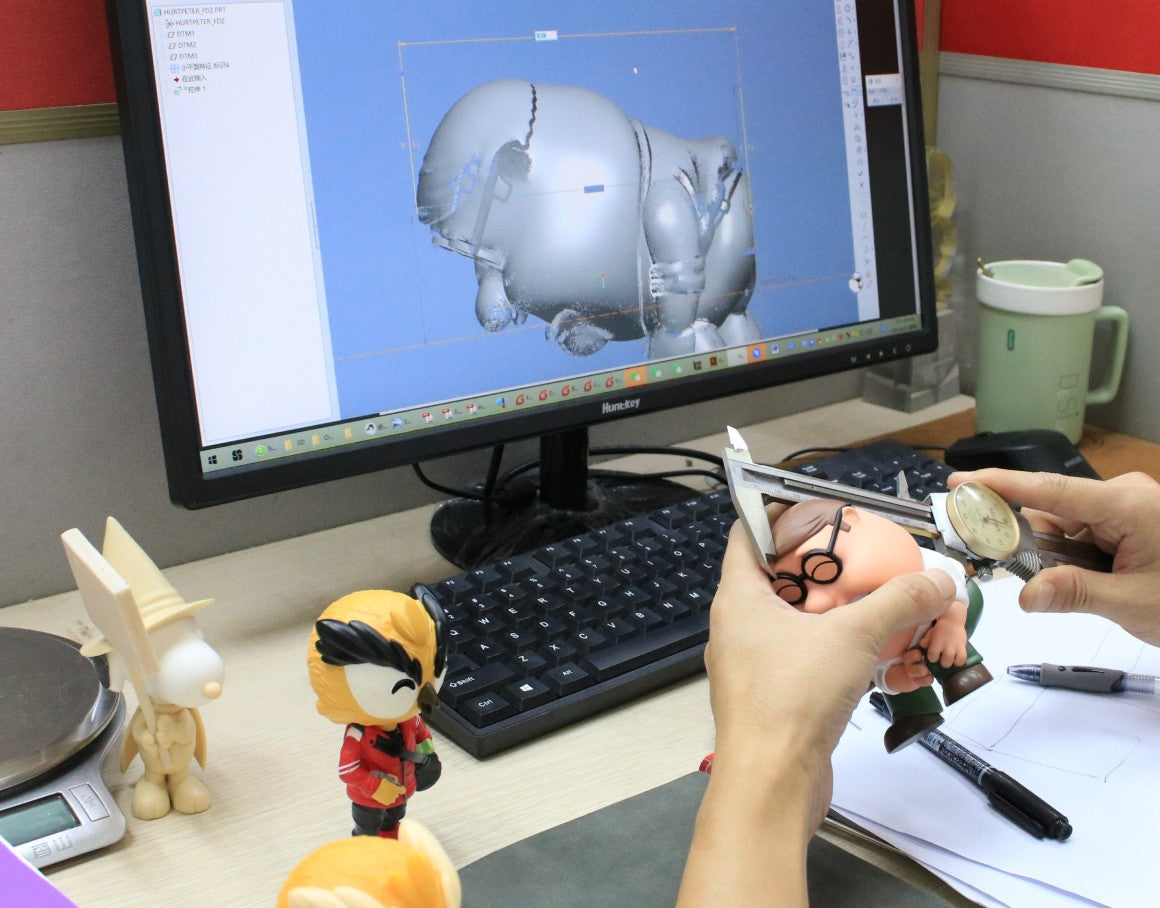

3D

The concept artist hands off the pantone color guide and turnaround files to our 3D modeling team. The OPJOYS sculptor will then create the first 3D version of the OPJOYS - basically molding a piece of "digital clay" into the figure. The initial 3D model is then shared with the creator, IP holder or owner for review.

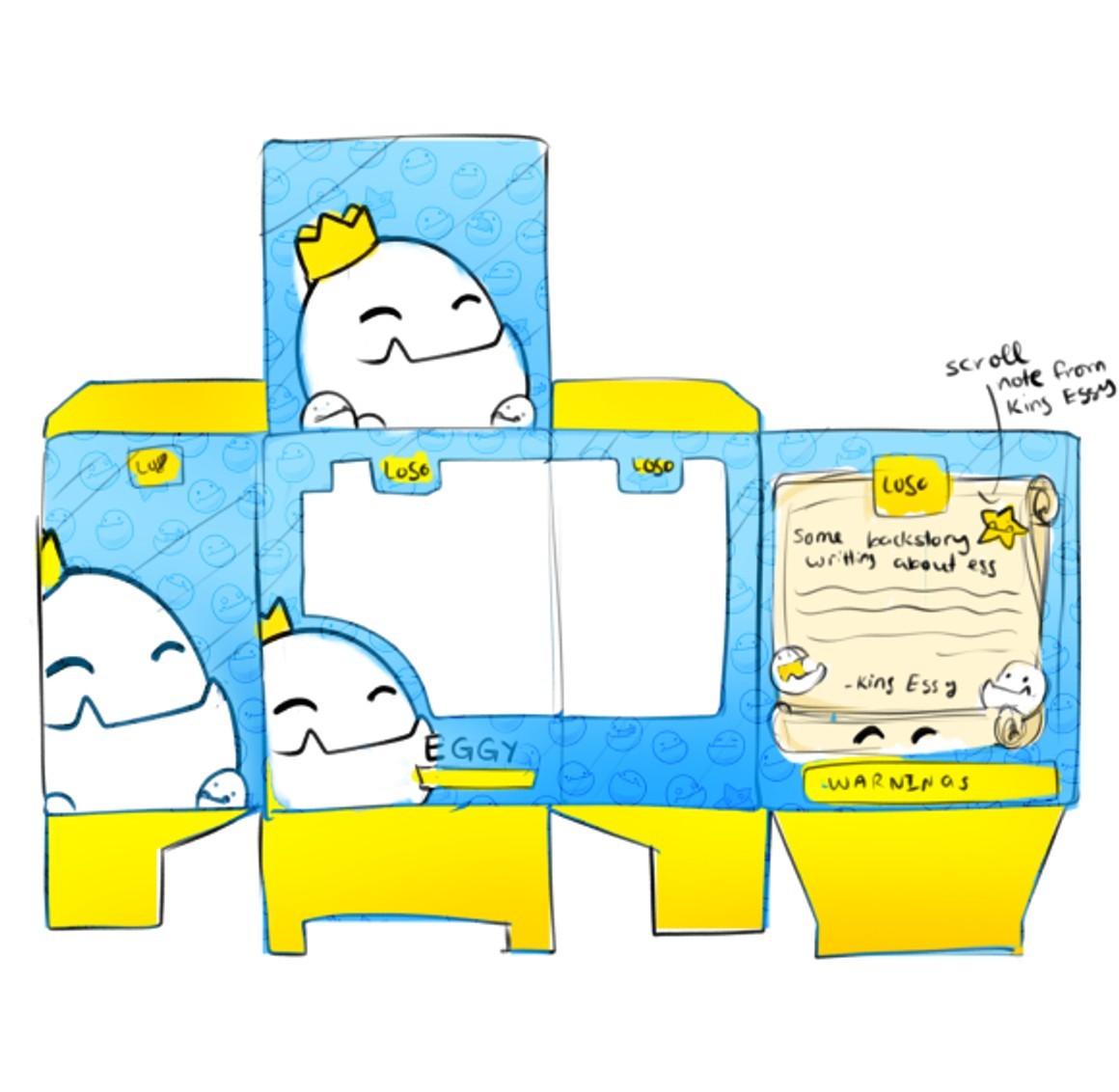

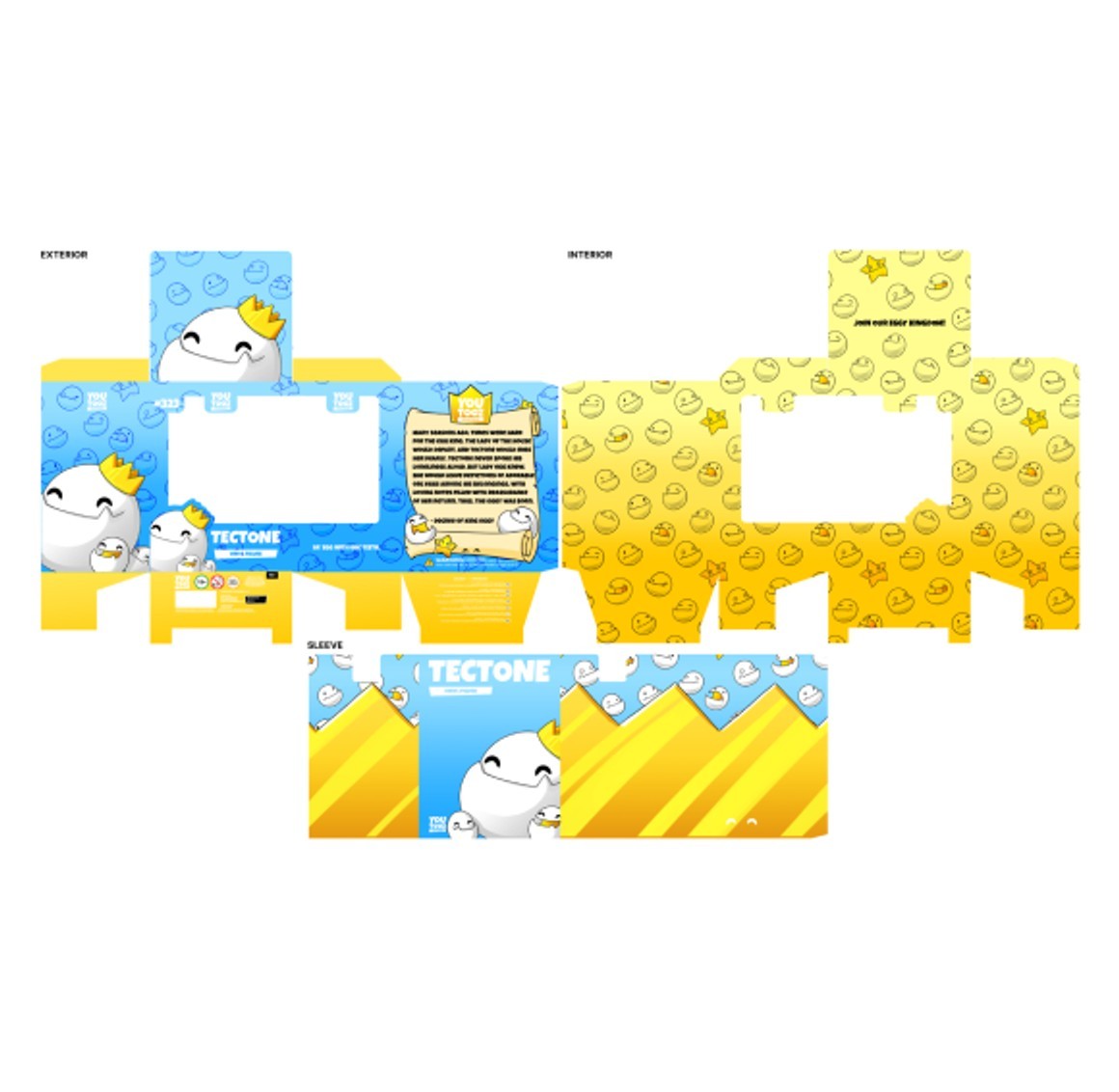

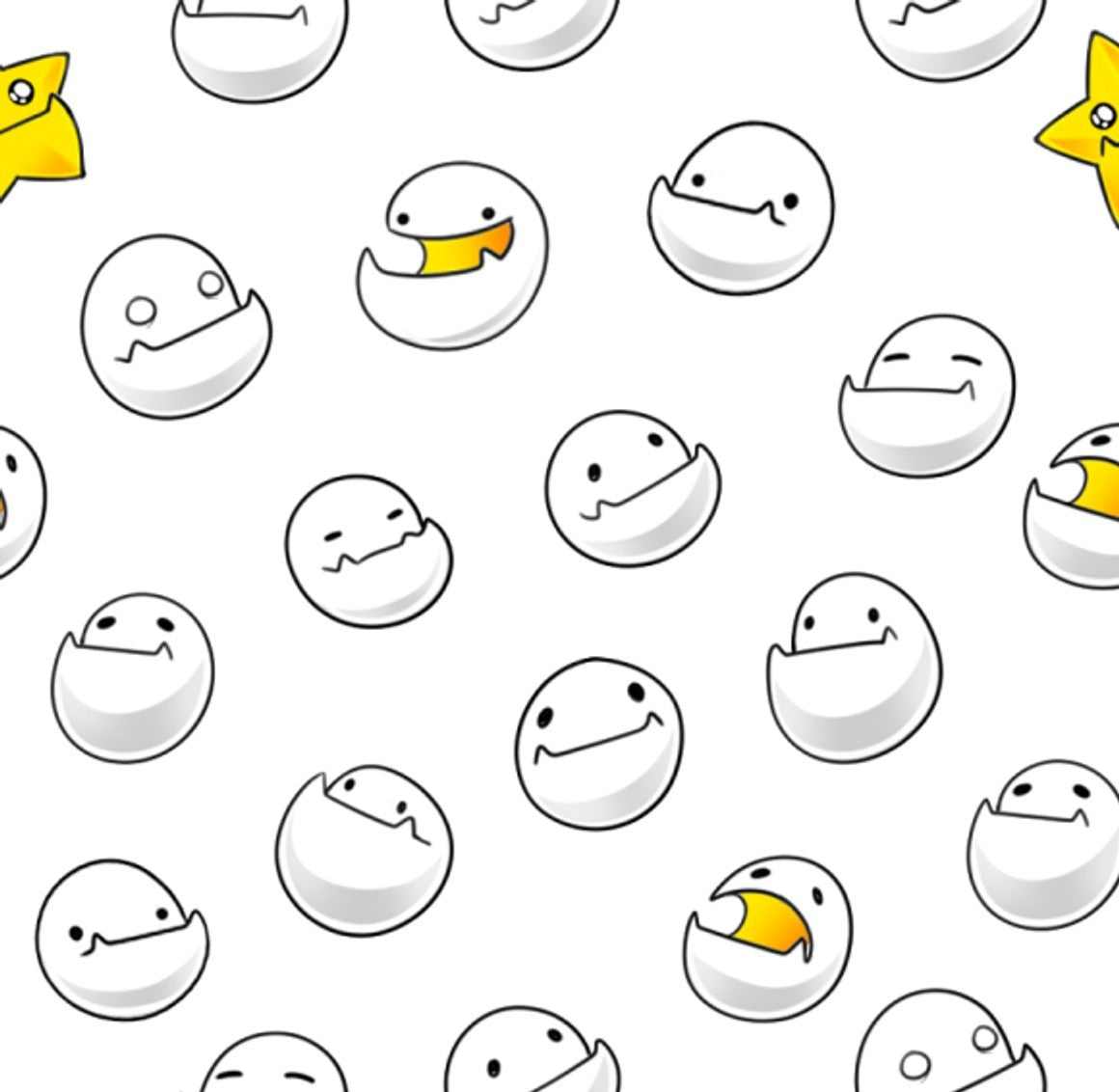

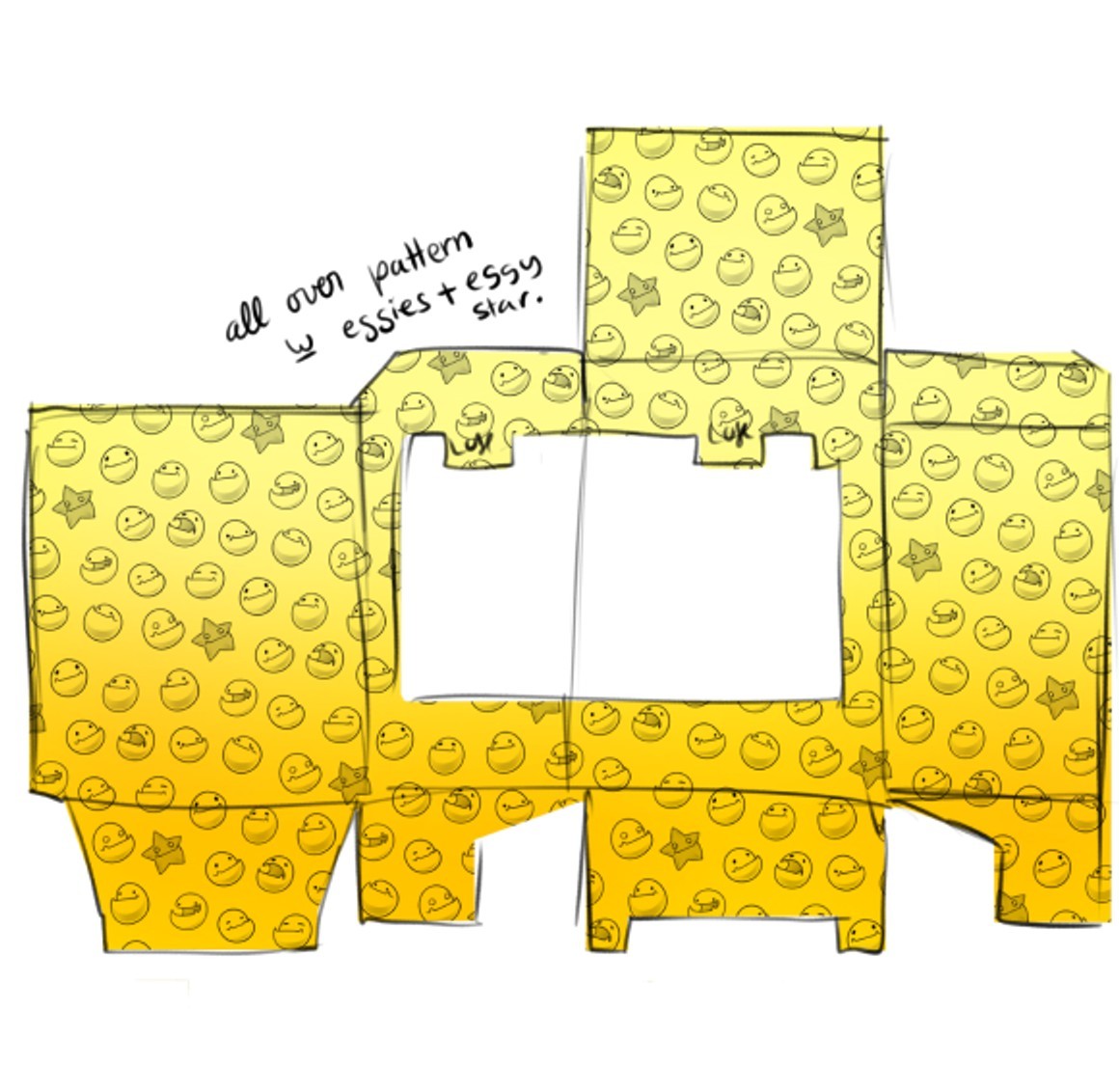

Packaging

While the OPJOYS sculptor is working on the 3D model, our packaging artists work with the creator or IP owner to sketch the window-box artwork. The artwork is a collaboration between the OPJOYS artist and the creator, IP holder, or owner covering the interior, exterior and sleeve. Brainstorming can be anything from describing the scene to be sketched or going over references from past content. Usually it takes 4-8 hours of design time to get the first version for the character owner to review and comment on.

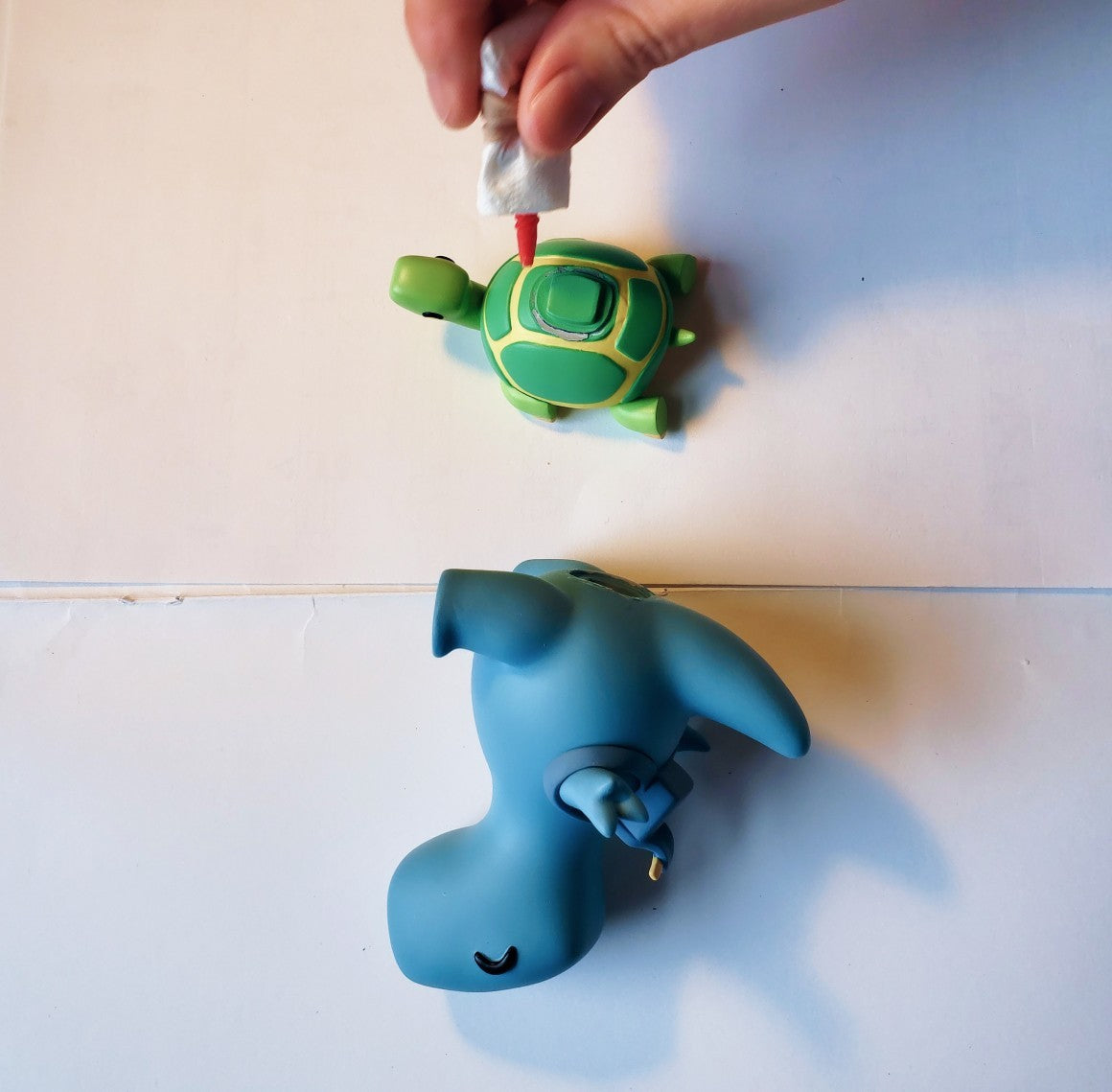

Sampling

After the packaging artwork and 3D model is complete, our design team hands off the character files to the OPJOYS manufacturing team. The first step in production is to create a 3D printed sample which is used to review how the OPJOYS will look in physical form.

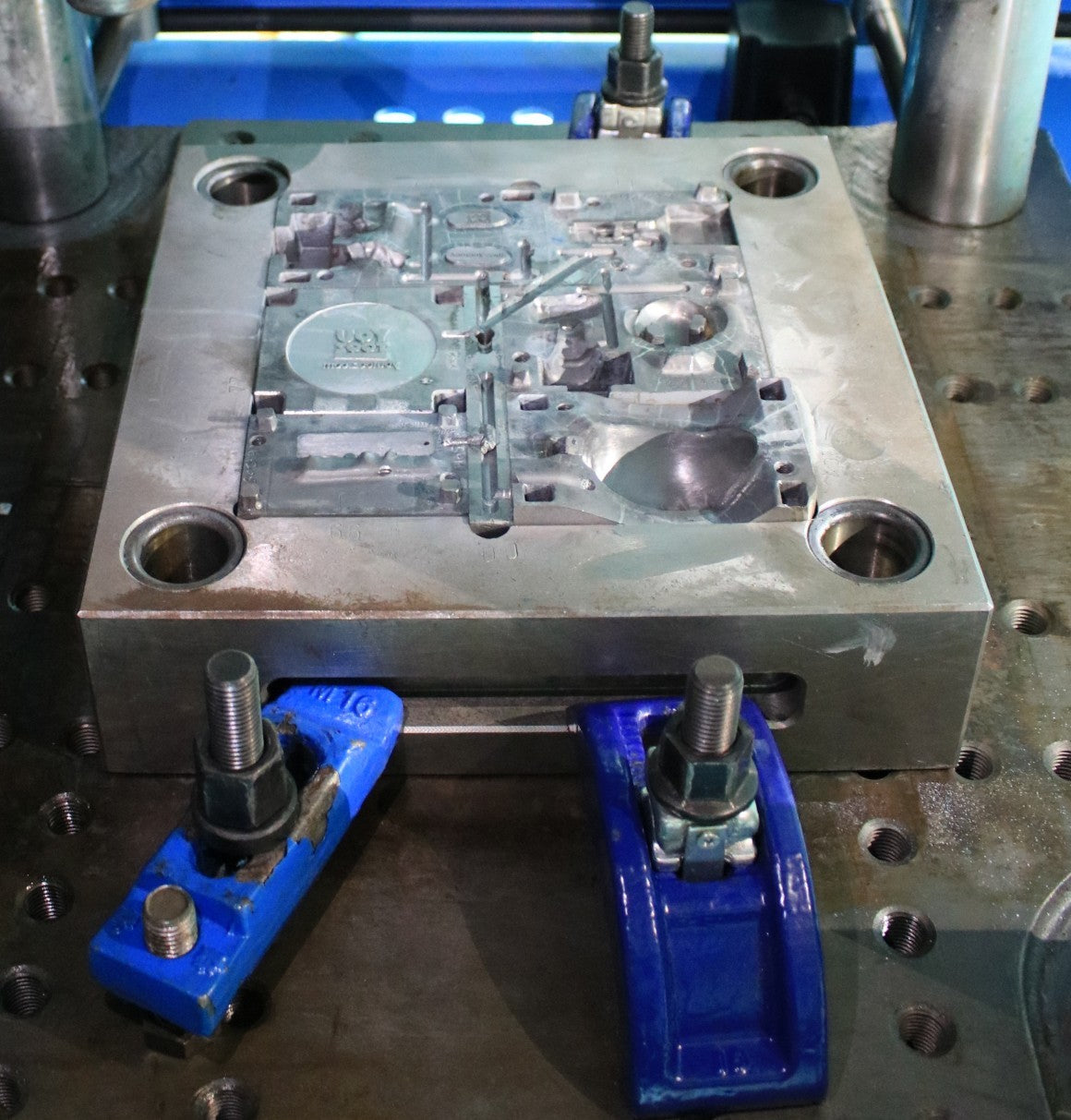

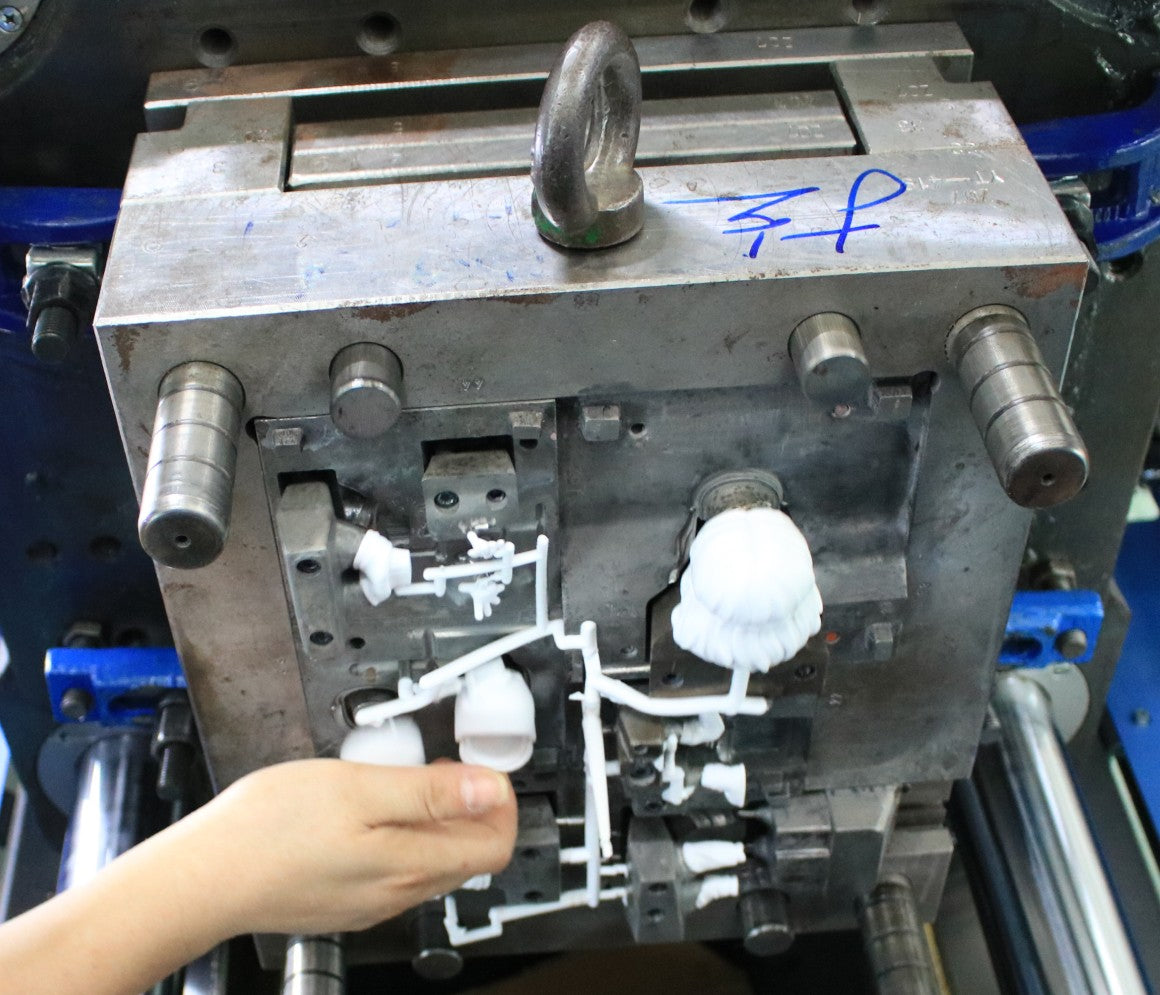

Molding

Once a sample has been approved by the creator or IP owner the steel-mold production begins. The steel is cut with a CNC machine to form each part and accessory of the OPJOYS. The more complex a design, the longer the mold takes. We've had some that have taken half a year to perfect. Once we're done with a mold, we recycle the steel so it can be reused in making a new figure in the future.

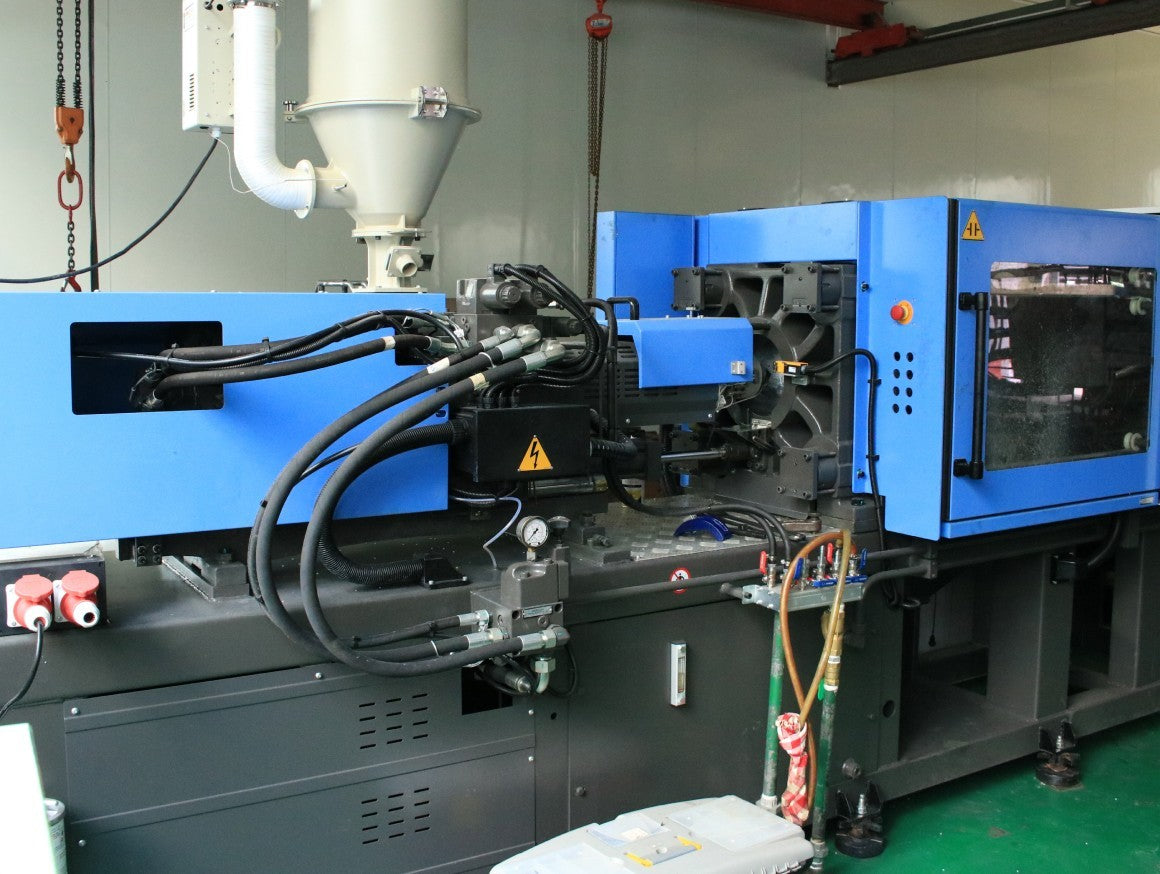

Vinyl Injection

With the mold finished, liquid vinyl is now injected into the mold and once cooled creates each piece of the OPJOYS. Part by part an OPJOYS comes together!

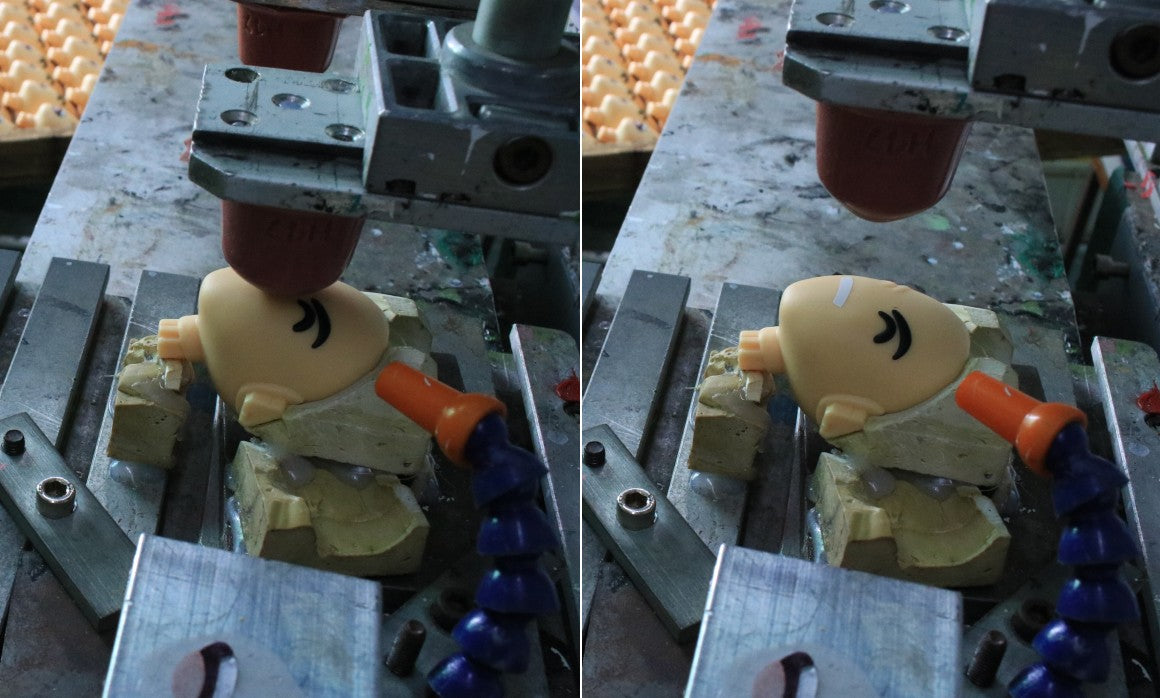

Assembling and Paint

After all the parts are created, the production team then assembles each OPJOYS figure by hand while meticulously painting details like eyes, clothes, and other accessories.

QA Design and pantone check

As production starts to come together, our quality assurance and quality control teams begin inspecting each figure for defects or inconsistencies. Once passed through review, the OPJOYS are ready to be placed inside their window box and get shipped to our warehouse.

Packaging and shipping

Once packaged in the window box and protective sleeve, each OPJOYS is placed into a protective case at our warehouse and then put into a carton, ready to ship out to you. Thousands of OPJOYS ship out every day.